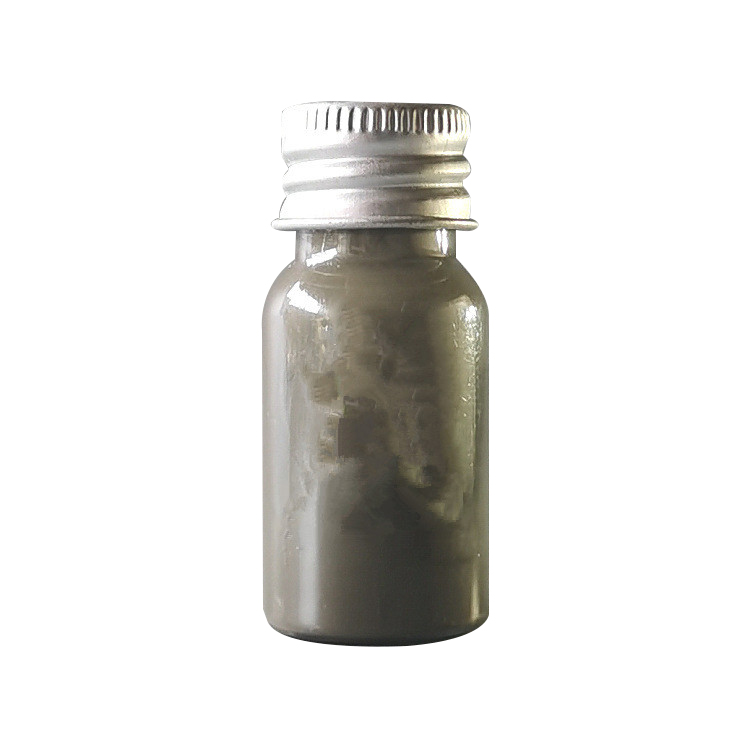

Large-Scale Production Method of Silver Nanoparticles

2025-07-08

Silver nanoparticles (AgNPs) have emerged as one of the most widely used nanomaterials due to their unique optical, antimicrobial, and catalytic properties. Their applications span across medical devices, textiles, electronics, and environmental technologies. As demand grows, developing reliable, scalable, and cost-effective methods for the large-scale production of silver nanoparticles becomes essential. This essay outlines the primary methods used in large-scale synthesis, emphasizing chemical reduction, green synthesis, and physical approaches, while also addressing the challenges and future directions in this field.

1. Chemical Reduction Method

The chemical reduction method remains the most commonly used technique for producing silver nanoparticles on an industrial scale. In this process, silver ions (typically from silver nitrate) are reduced to metallic silver using chemical reducing agents such as sodium borohydride, citrate, or hydrazine. Stabilizing or capping agents, like polyvinylpyrrolidone (PVP) or polyethylene glycol (PEG), are added to prevent agglomeration and control particle size and shape.

Advantages:

High yield and reproducibility.

Scalability for mass production.

Control over particle morphology with optimized parameters.

Disadvantages:

Use of potentially toxic chemicals.

Environmental concerns due to waste disposal.

2. Green Synthesis Approach

To address the environmental limitations of chemical synthesis, green methods have been developed using plant extracts, microorganisms, and other natural reducing agents. Plant-based synthesis, in particular, uses extracts from leaves, fruits, or seeds to reduce silver ions into nanoparticles.

Advantages:

Eco-friendly and sustainable.

Eliminates the use of hazardous chemicals.

Suitable for biomedical applications due to biocompatibility.

Challenges:

Lower reproducibility compared to chemical methods.

Difficulties in standardizing raw materials.

Slower reaction rates and lower concentration outputs.

3. Physical Methods

Physical methods such as evaporation-condensation, laser ablation, and microwave-assisted synthesis are also used in large-scale nanoparticle production. These techniques generally do not require chemical reagents, thereby reducing contamination risks.

Evaporation-Condensation:

This method involves heating silver in a controlled atmosphere to produce vapor, which then condenses into nanoparticles. It is often conducted in inert gas flows.

Laser Ablation:

Silver metal is ablated in a liquid medium using a high-powered laser, producing colloidal silver nanoparticles.

Microwave-Assisted Synthesis:

Microwave heating accelerates chemical reactions and promotes uniform nanoparticle formation, making it suitable for rapid large-batch production.

Advantages:

High purity products.

No chemical contamination.

Disadvantages:

High energy consumption.

Expensive equipment.

Limited scalability in some cases.

4. Challenges and Considerations for Industrial Production

Despite the availability of various synthesis methods, scaling up nanoparticle production introduces several challenges:

Uniformity and consistency in size and shape across batches.

Cost-effectiveness, especially in terms of raw materials and energy usage.

Regulatory and safety compliance, particularly for applications in food, medicine, and cosmetics.

Waste management and environmental impact of large-scale chemical processes.

5. Future Outlook

The future of silver nanoparticle production lies in optimizing synthesis protocols to balance efficiency, environmental responsibility, and cost. Hybrid methods combining green and chemical processes, advanced automation, and real-time quality monitoring systems can help achieve better control and scalability. Additionally, advances in nanotechnology and materials science will likely enable more precise tailoring of nanoparticle properties to suit specific industrial applications.

Conclusion

Large-scale production of silver nanoparticles is achievable through multiple methods, each with its own strengths and limitations. Chemical reduction dominates current industrial practices due to its efficiency, while green synthesis offers a more sustainable alternative. Physical techniques provide high-purity products but may face scalability challenges. Moving forward, integrating environmentally friendly practices with cost-effective technologies will be key to meeting the growing demand for silver nanoparticles in diverse sectors.

As a professional manufacturer and supplier, we provide high-quality products. If you are interested in our products or have any questions, please feel free to contact us.